The BoltStress Process: How We Do What We Do

Fatigue is the number one cause of bolt failure. When there is too much fatigue for the bolt to handle, it eventually results in a crack. Over time, this crack deepens until the whole thing fractures. A single bolt failure can put an entire milling operation to a stop - and that is a situation we help businesses avoid. BoltStress exists to make sure all bolts are fully functional so your enterprise can stay operational.

We follow a four-step ultrasonic bolt stress measurement process. Allow us to walk you through it.

Step 1: Analysis

First, we take a look at key measurements. We inspect the current stress the bolts handle and check if it is at the optimal level. We adjust torque settings and identify which bolts experience the most losses. We also gauge relaxation - how much there is and when it happens. Finally, we assess which bolts should be prioritized during maintenance.

Step 2: Elimination of Failure Modes

The second step is all about checking if the bolts work properly. We define the priority bolts during the re-lining and re-torque processes. We also review the performance of both priority and non-critical bolts while in service.

Step 3: Reduction of Re-Torque Duration

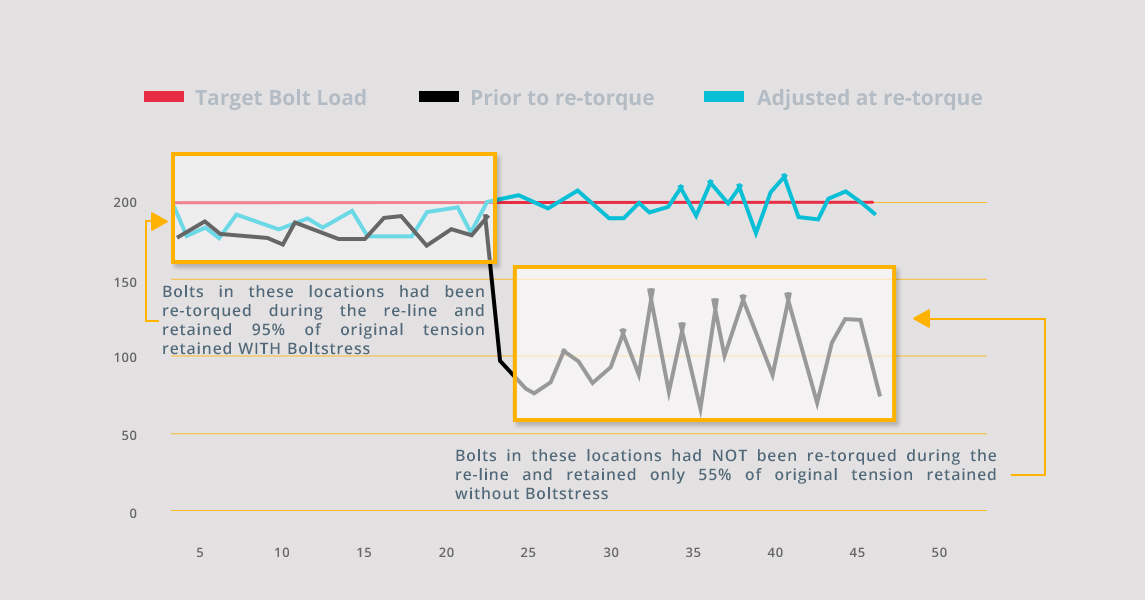

When we begin a re-line process, we make sure all bolts are tight enough for daily operation. We check the bolts during a re-torque as well and adjust those bolts that need it. This process alone cuts down the work by half. An adjusted bolt typically retains 95% of its original tension, while those that have not been re-torqued operate at only 55% of the original tension.

Step 4: Elimination of Re-Torque

The last step involves a review of all findings in the process. We also streamline the process for re-torque while a re-line is underway. Finally, we collect results, review findings, and monitor the performance of all bolts.

We believe that our systematic approach gives us an edge over our competitors. With our help, we can cut your costs and increase your production by significant margins. Get in touch with us today and let us work together.